Identifying Oxidized Cooking Oil

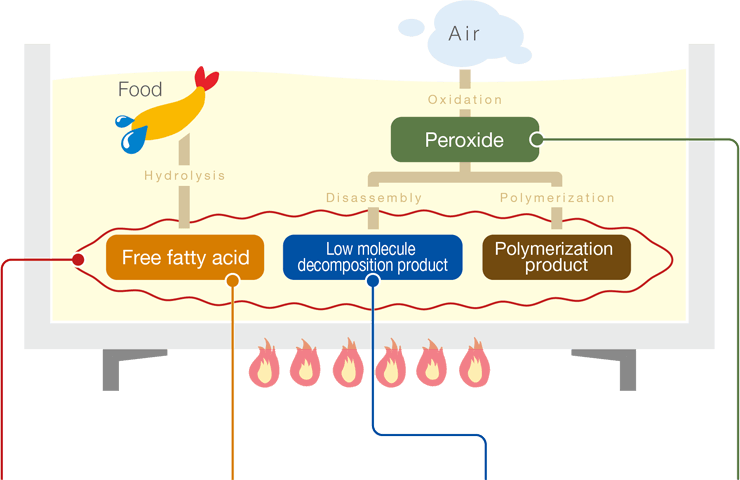

Types of oxidation

Determining oil oxidation at home can be done by color or smell, but in professional kitchens and production sites, the methods below are used.

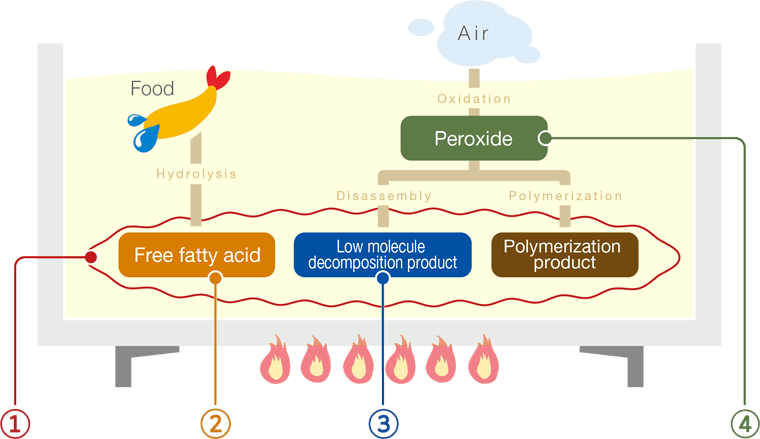

①Total Polar Materials

(TPM)

A method used to determine the degradation of frying oil. Total Polar Materials (TPM) refers to all products present in frying oil due to oxidation processes, including free fatty acids, products of low molecular weight decomposition, and polymerized substances. The EU has adopted a value of 25 to 27% as their acceptable upper limit for fats and oils.

②Acid Value

(AV)

Acid Value or AV is an index that denotes the amount of free fatty acids caused by hydrolysis. Acid value is a suitable method for evaluating the degree of oxidation for frying oils. Many AV test strips, which can be easily measure the value, are used at food production sites.

③Carbonyl Value

(CV)

It is a measurement denoting the amount of aldehyde and ketone produced in frying oils to determine degradation. Carbonyl compounds can be a good indicator of thermal oxidation. In addition, as the threshold is small, it will impact the smell of fats and oils greatly.

④Peroxide Value

(POV)

Peroxide is generated when oil is exposed to air, causing the unsaturated fatty acids to absorb oxygen. Peroxide value can also be used to measure hydroperoxide but for frying oil the indicator is by decomposition or polymerization.

Oil Quality Standards

Determining oil oxidation at home can be done by color or smell, but in professional kitchens and production sites, the methods below are used.

| Instant noodles | The acid value of fats and oils contained in noodles should not exceed 3 or the peroxide value should not exceed 30. | Standards for Foods, Food Additives | |

|---|---|---|---|

|

In fats and oils of noodles dried by oil treatment should be 1.5 or less. The acid value of fats and oils used for oil processing of noodles should be 1.5 or less. |

Japanese Agricultural Standard | ||

|

Confectionery processed with fats and oils (containing 10% or more of fats and oils) |

Selling products that conform to the following (a) and (b). (a) For confectionery products, the acid value of fats and oils contained in their products should not exceed 3, and, the peroxide value should not exceed 30. (b) The confectionery should not exceed an acid value of 5 or more in the fats and oils contained in the product or, the peroxide value should not exceed 50. |

Confectionery Guidelines | |

| Bento box and side dish |

As raw materials: Use those with an acid value of 1 or less (but excluding sesame oil) and a peroxide value of 10 or less. Frying with fats and oils: If the acid value exceeds 2.5, replace with fresh fats and oils. |

Health Code for Lunch Box and Side Dish | |

| Western-style confectionery |

(1) Component specification of raw materials: acid value 3 or less, peroxide value 30 or less (2) Products shall conform to the following standards ①The acid value of fats and oils contained in the product does not exceed 3. ②The peroxide value of fats and oils contained in the product does not exceed 30. |

Healthy Norms of European-style Confectionery | |

| Edible vegetable oils and fats | Oil with low degree of purification | Acid value of 0.20 to 4.0 or less. (Cottonseed, sesame, rapeseed, peanut, olive, palm olein, palm stearin, mixture, flavor oil) | Japanese Agricultural Standard |

| Refined oil | Acid value of 0.20 or less (Olive oil has an acid value of 0.60 or less) | ||

| Salad oil | Having an acid value of 0.15 or less (the one prepared with olive oil has an acid value of 0.40 or less) | ||

| DOM-24 | Test Strip | Titration | |

|---|---|---|---|

| Ease of measurement |

Simple operation |

|

|

| Measurement time |

|

|

|

| Display |

|

|

|

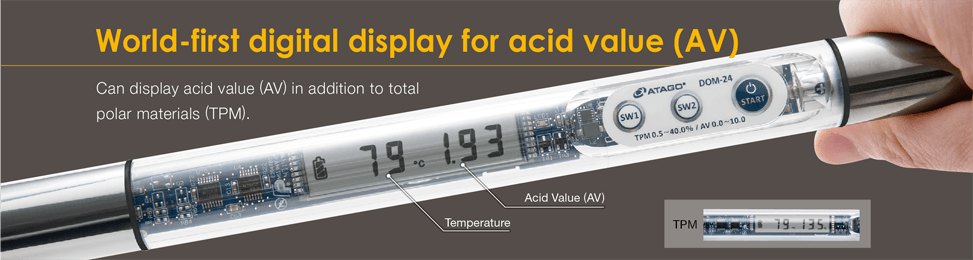

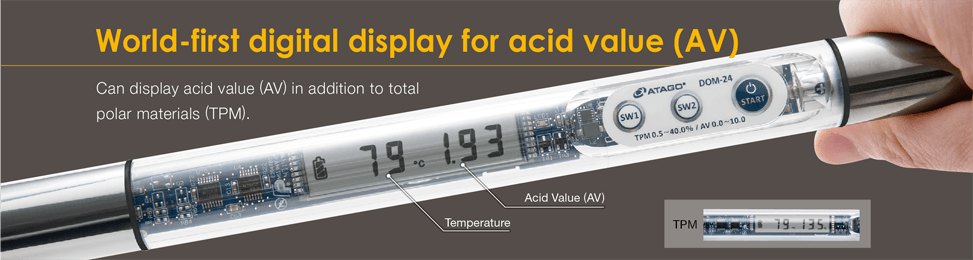

Frying Oil Monitor

DOM-24

Identifies the Best Time to Replace Oil

・Allows you to safely cook delicious fried foods

・Lowers oil usage and reduces waste

・Lower costs by using oil right up until it needs to be replaced

Specifications

| Cat.No. |

9341(DOM-24) 9347(DOM-24 X3) |

|---|---|

| Measurement range |

TPM : 0.5 to 40.0% AV : 0.00 to 9.99 Temperature (˚C) : 0 to 225˚C Temperature (˚F) : 32 to 437˚F |

| Resolution |

TPM : 0.5% AV : 0.01 Temperature : 1˚C⁄1˚F |

| Measurement accuracy |

Approx. ±0.2(Varies with user’s scale setting.) TPM : ±2.0% Temperature : ±1˚C / ±2°F (20 to 200˚C / 68 to 392°F) |

|---|---|

| Temperature compensation range |

0 to 225˚C (accuracy guaranteed from 20 to 200˚C) 32 to 437°F (accuracy guaranteed from 68 to 392°F) |

| Power supply | Size AAA alkaline battery × 2 |

| International protection class | IP67 |

| Dimension and weight | 22(ø)×490(w)mm, 400g(Main unit only) |

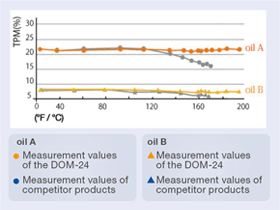

Stable and reliable measurement values

The DOM-24 is equipped with automatic temperature compensation (ATC), making it capable of measurements at a wide temperature range of 0 to 225˚C. The DOM-24 can provide stable and reliable measurement values, even at high-temperatures.

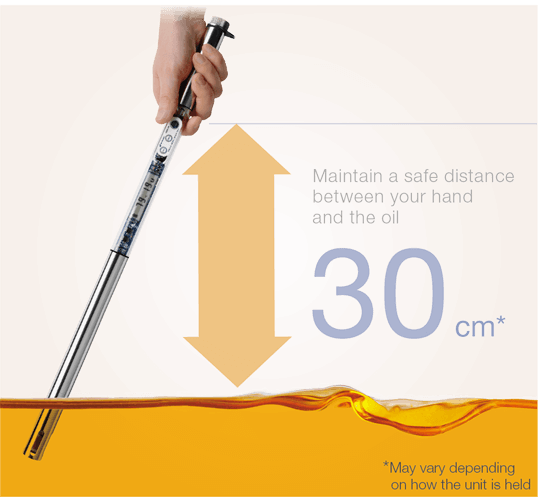

Avoiding burn injuries

To improve the safety of employees and contribute to the reduction in the risk of burns.

Rated IP67 (Water resistant)

Designed to be used safely around water. Wash away stubborn oil stains with regular dish soap under running water. Instrument will survive accidentally being dropped in water.

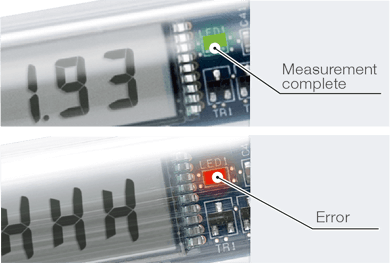

Easy confirmation with LED

Can be used to stir the oil

Due to oil having layers, temperature and degradation levels may not be uniform throughout. Stirring the oil with the product can produce more consistent results.

Sturdy construction with a protective cover

Impact-resistant body

Confirmed to continue working even if dropped accidentally from waist height so you can relax and let all of your employees use it without worry.

Atago has a communication function.There is no need to record each measurement.

Excellent operability with the touch of a button.It has a reputation for being easy to use even in the field.

Our products are made entirely in Japan with high quality.